Have Questions? Need a Quote? Contact Us!

PTFE Coated Fiberglass Fabric

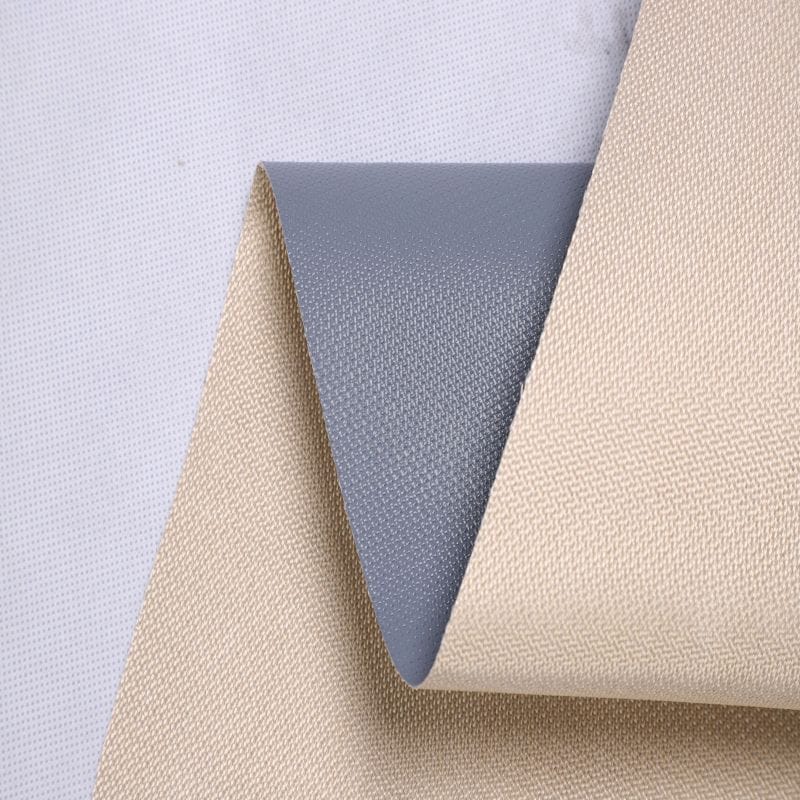

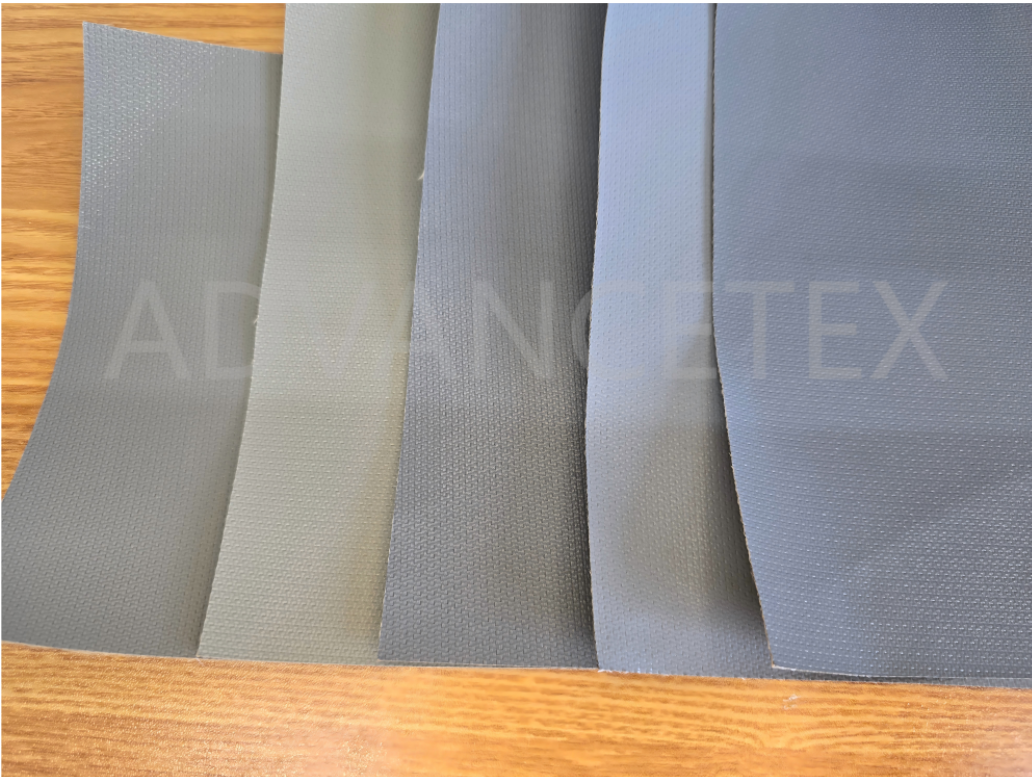

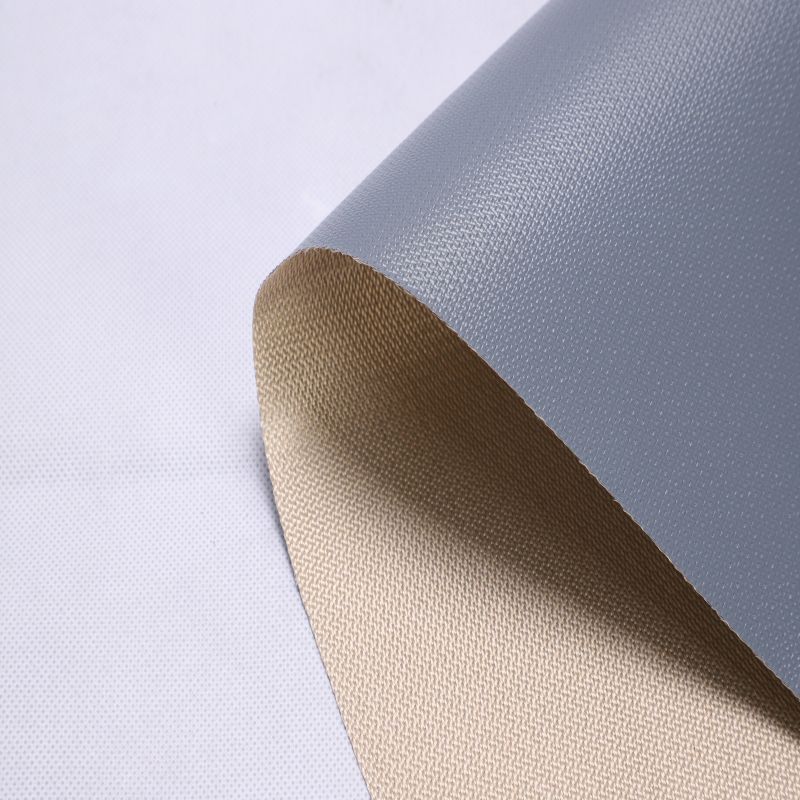

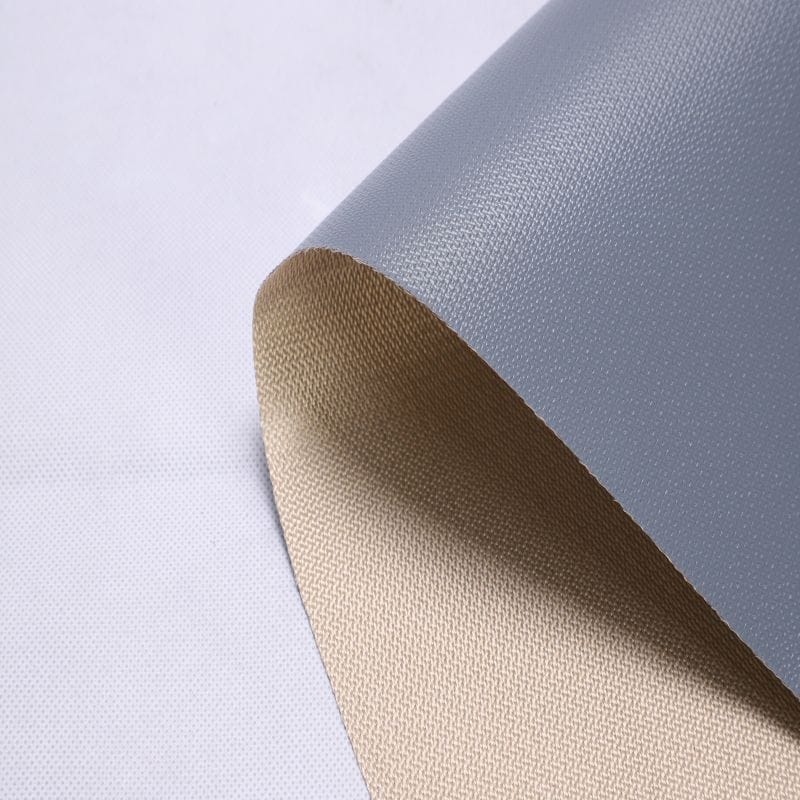

PTFE coated fiberglass fabric, also known as polytetrafluoroethylene (PTFE) coated fiberglass fabric, consists of a fiberglass fabric substrate with a gray PTFE coating.

Due to its excellent thermal insulation properties, it is often used to make insulation jackets/covers, providing insulation for valves, pumps, semiconductor equipment, and more.

Typical Applications of Insulation Jackets/Covers Made from PTFE Coated Fabric:

- Pipe Insulation

- Valve Insulation

- Equipment Insulation

- Special Environments