Have Questions? Need a Quote? Contact Us!

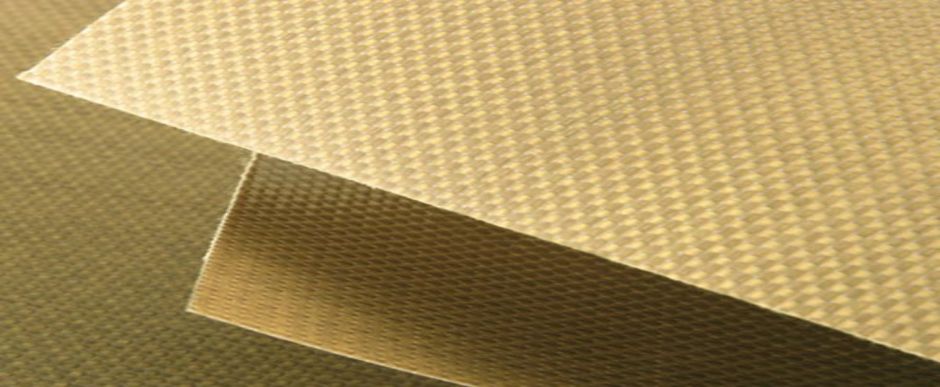

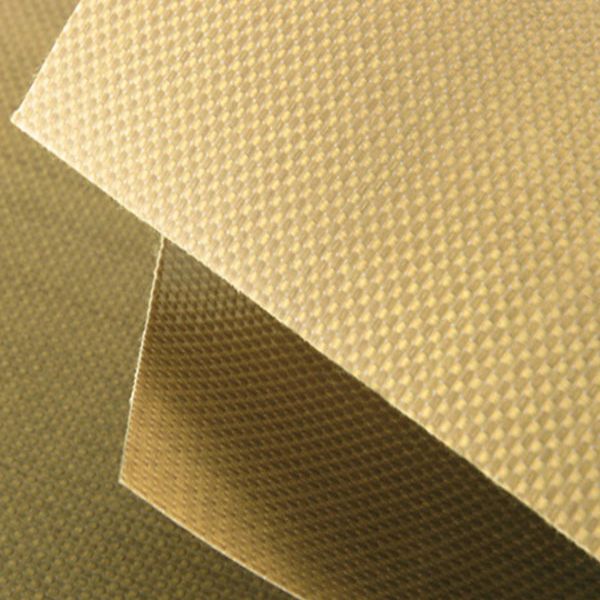

PTFE Coated Aramid Fabric

PTFE Coated Aramid Fabric is a composite material that combines the high-performance characteristics of aramid fibers with the non-stick and heat-resistant properties of polytetrafluoroethylene (PTFE) coating. This combination results in a fabric suitable for a wide range of industrial applications where strength, heat resistance, and non-stick properties are essential.

Key Features:

- Aramid Fiber Strength: Aramid fibers, known for their exceptional strength and durability, contribute to the fabric's robustness.

- Heat Resistance: The PTFE coating enhances the fabric's ability to withstand high temperatures, making it suitable for applications in elevated heat environments.

- Non-Stick Properties: The PTFE coating provides a non-stick surface, preventing adhesion of substances and making it easy to clean.

- Chemical Resistance: The fabric exhibits resistance to various chemicals, contributing to its versatility in different industrial settings.

- Flexibility: Despite its strength, the fabric remains flexible, allowing for ease of use in various applications.

- Weather Resistance: It can withstand exposure to different weather conditions, making it suitable for outdoor applications.

Applications:

- Conveyor Belts: Used in the production of conveyor belts for applications where non-stick properties are essential.

- Release Sheets: Ideal for manufacturing release sheets in processes where materials need to be easily released without sticking.

- Expansion Joints: Applied in fabric expansion joints in industrial settings for its durability and resistance to heat and chemicals.

- Heat Sealing: Utilized in heat-sealing applications where a non-stick surface is necessary.

- Protective Covers: Employed in protective covers for machinery and equipment due to its strength and weather resistance.