About Butterfly Valves:

Butterfly valves members of a group of valves called quarter turn valves, which are all controlled manually by turning a handle 90 degrees. Butterfly valves work similarly to ball valves; both valve types have a component inside that prevents flow when the handle is turned to the “off” position. The main difference between the two valves is that the butterfly valve uses a flat, round, metal disk called a butterfly to regulate flow, whereas the analogous component within the ball valve is a spherical disk appropriately known as a ball. One advantage of a butterfly valve is that it can be used for throttling — that is, to regulate rate of flow — in addition to reliably turning flow on and off. Butterfly valves come in many varieties: three main types are resilient (or concentric) butterfly valves, high-performance (also known as doubly eccentric or double-offset) butterfly valves, and triple-eccentric (or triple-offset) butterfly valves. The two most common styles of butterfly valves are the wafer and lug style. Butterfly valves have a wide range of applications, from steam systems to residential hot and cold water pipes to carburetors to offshore pipelines.

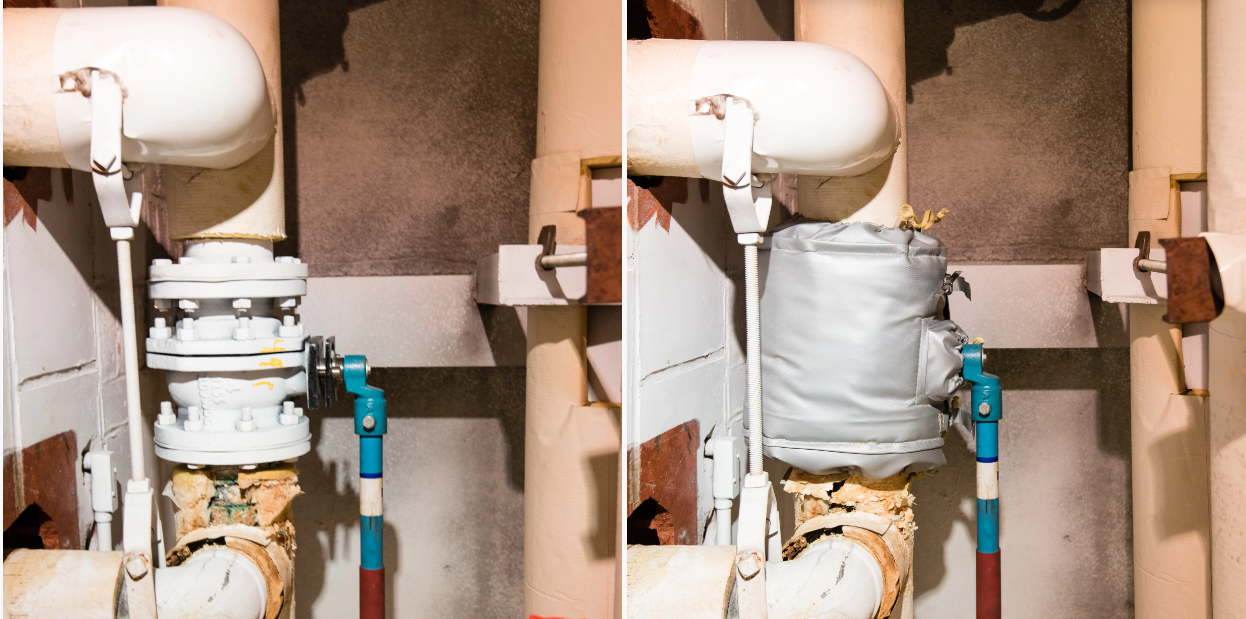

Insulating Butterfly Valves

The body of a butterfly valve is almost always made of metal, typically steel. Insulation becomes desirable in high temperature applications like steam systems, since the steel radiates a good deal of valuable heat. Butterfly valves may also need to be insulated if they are used in water pipes that exist in environments where freezing is a risk.

Butterfly valves are not candidates for stay-in-place insulation, however. One reason is that butterfly valves have a handle and odd shape. The second reason is that butterfly valves may require disassembly for inspection and maintenance, which would require some destruction of the hard insulation. For many applications, it is recommended that personnel inspect the seat ring of the valve and inspect for corrosion, especially in susceptible environments and when the material is carbon steel. In addition, regular preventative maintenance such as lubrication and replacement of packing and gasket may be recommended. Inspection and maintenance is particularly important in plants and large scale operations because the failure of one butterfly valve can potentially result in plant shut-down.