About Plug Valves

Plug valves (sometime called stop-cock valves or cock valves) are a type of valve that features a cylindrical or tapered “plug” with one or more openings. The plug can be rotated so that the opening(s) either allow or block flow. Plug valves are considered to be quarter-turn valves because the flow is turned on or shut off with a 90° rotation (except for some plug valves with more than two ports). The two main types of plug valves are lubricated and non-lubricated. A variety of actuators may be used from manual handles and hand wheels to pneumatic actuators. Plug valves are typically not recommended for throttling. Plug valves are high capacity valves often recommended for use when quick and frequent shut-off and on-off operation is needed.

Plug valves have many different applications. Household gas lines often use plug valves. Plug valves are often used for high-temperature applications and for regulating flow of (often potentially dangerous) chemicals. Plug valves are also sometimes used in steam systems. Plug valves are commonly found in chemical-processing plants, oil and fuel pipelines and power plants.

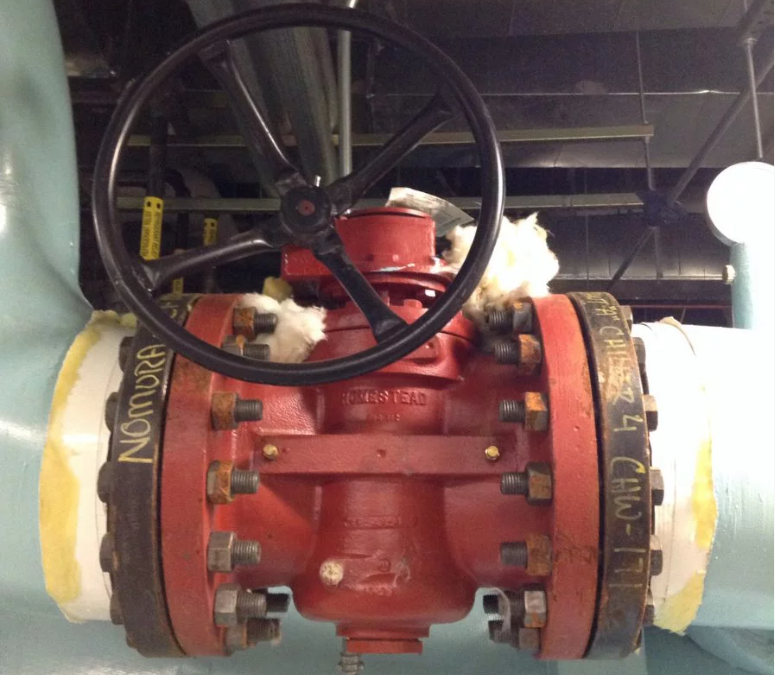

Insulating Plug Valves

Insulation is often recommended for metal plug valves in high temperature settings. Since plug valves often undergo severe wear and tear in corrosive environments, inspection and maintenance is typically necessary. It is also not uncommon for plug valves to become hard to operate or stuck and lubrication or troubleshooting may be necessary. Because of the need for access and plug valves’ sometimes difficult shape, stay-in-place insulation is frequently impractical