About PRVs

Pressure-reducing valves go by a few names such as PRVs or pressure regulators. Regardless of the name, the essential function is the same: to lower the pressure of high-pressure liquids or gasses to meet the need of particular application, regardless of pressure fluctuations in the liquid or gas that flows in the valve. Pressure-reducing valves have many different specific applications, from municipal water lines to SCUBA tanks to steam systems in industrial plants.

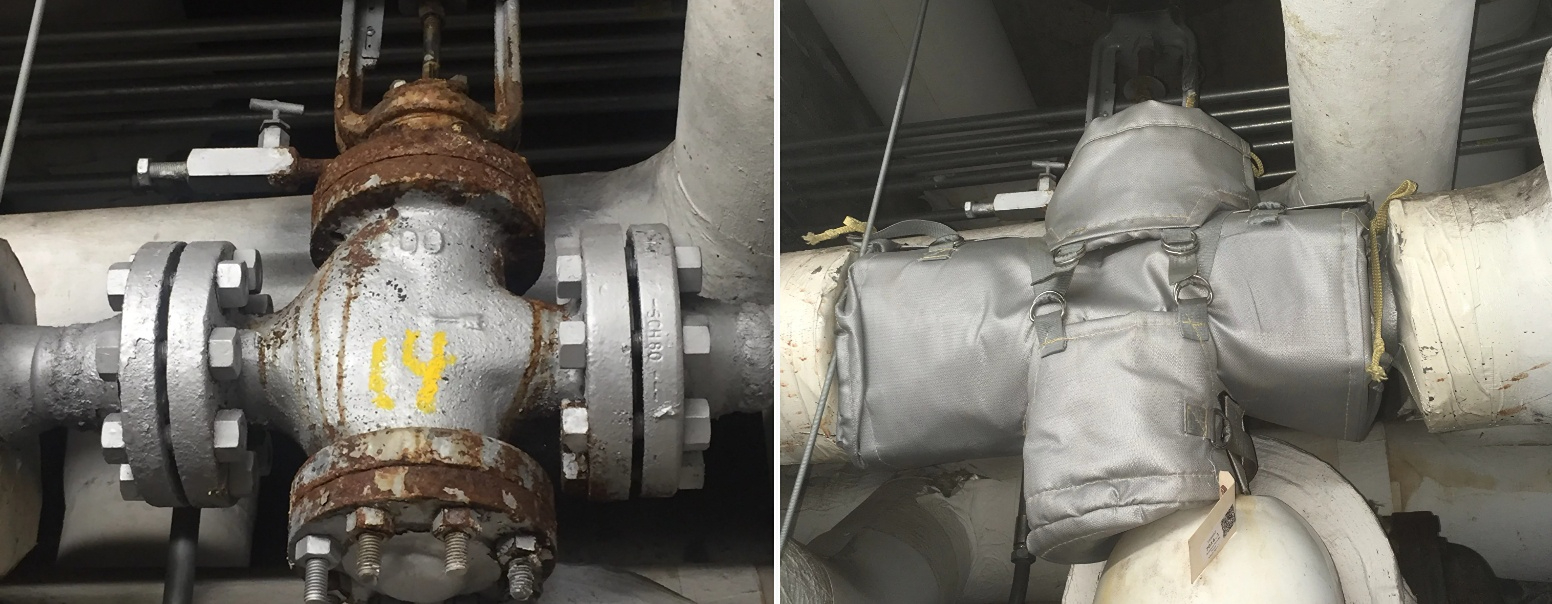

Insulating PRVs

It is in steam-using plants where we most often see the need for insulation covers on pressure-reducing valves. In these plants, the steam is often generated at very high pressures and then reduced via the PRVs to safely meet the specific requires of the steam-using components and equipment. Should the PRV allow too much steam to pass the receiving component or equipment may not be able to handle the pressure; should the PRV reduce the pressure too much, the receiving equipment may not work optimally. For this reason, PRVs must be regularly monitored, maintained, and adjusted – and this is why they cannot be insulated with traditional stay-in-place insulation.

However, steam is hot; and pressurized steam is often even hotter. While the pipes in which this steam travels are often well insulated, the PRVs commonly provide a “weak spot” for heat to escape via the conductive metal surface area of the valve. Removable insulation covers can help. Removable insulation covers can keep heat from escaping the pressure-reducing valve and can also help eliminate the safety hazard of exposed hot metal